In part 2 of this special feature from Tobacco Business Magazine focuses on the machines involved in making some premium cigars and the people involved in the process. For part 1, click here.

The Machines

Smaller cigars have always had a place in the tobacco marketplace. Even today, some of the leading manufacturers of premium cigars also offer consumers smaller cigars that can be enjoyed in a short amount of time. Quality and consistency are two factors every company must focus on in order for their small cigar to have any success in retail stores and to connect with consumers.

“It is a delicate balance between great tobacco—the farms, the farming process, the fermentation, the aging, the storage, the selection of top-grade tobacco—and a high level of expertise from the quality management and production team,” Villiger Cigars North America president Rene Castaneda explains.

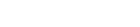

Cigarillos and short filler cigars cannot be made by hand like a regular premium cigar. These smaller cigars require the use of machines that not only automate the production process but also help ensure the quality of the product.

“Working with machines makes the end result often more reliable. All [production] steps are automated—the act is the same every time, which makes the consistency even better than with manual cigars,” explains Emmanuel Claerbout, J. Cortes’ export manager. “People can and will always make mistakes or have an off-day. Machines usually don’t.”

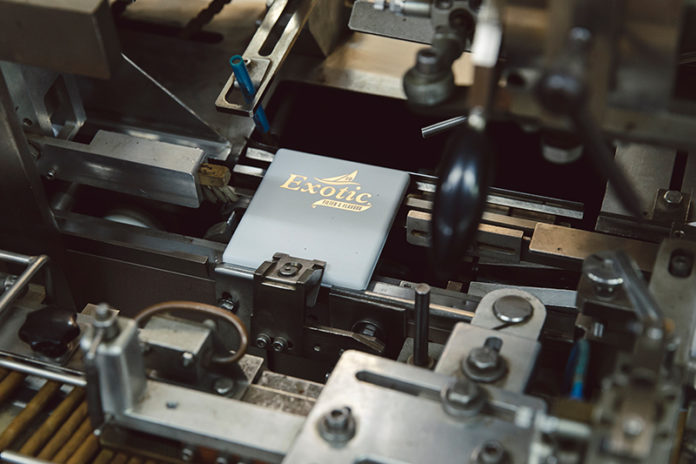

There are different machines used to make small-format cigars. J. Cortes uses machines made by ENSA, ITM and PMB to help it make cigar products. It also uses machines made by ATD Machinery, a subsidiary of Highlands Holding, the parent company of Royal Agio Cigars, to assist with the packing of its cigars. Villiger’s cigarmaking machines are made by Hauni, which is based in Germany, and Sollas, which is based in the Netherlands. Villiger also has its own workshop and engineers that modify the machines based on the company’s specific needs. Royal Agio Cigars has a unique situation in that the machines it uses to make cigarillos are made in-house at ATD Machinery. Both of these companies, as well as others, are privately held by the Wintermans family, which established Royal Agio Cigars in 1904, thus giving the company the longest history and heritage of producing small cigars.

“It is interesting to note that ATD is the largest supplier of cigar-producing machinery in the world. You could say that we’re confident we have the best machinery available at any given time to be able to consistently produce the best premium cigarillos in the world,” explains Florez-Estrada.

Similar to the role artisans play in the quality of handmade cigars, these machines play a major role in the quality and consistency of these smaller cigars. Today, the advanced machinery used to make these unique products helps improve construction, quality and overall consistency, three attributes that are key to the enjoyment and success of any tobacco product in the marketplace. The small cigars made with these machines are often sold at an affordable price—not because the tobacco used is low-grade but because the machines help create efficiency in the production process.

For those companies that make cigarillos or other small cigars, machines are able to work with the smaller format better than human hands can. Machine-made cigars are made with high-quality tobacco and are produced with consistency and at an affordable price point. Villiger approaches its machine-made cigars as it does its premium handmade products, putting blend, aroma and flavor first while focusing on the overall smoking experience. These small-format cigars are marketed as the perfect alternative product for when time is limited but the smoker still wants a premium smoke. The biggest challenge many manufacturers face when marketing their machine-made products in the U.S. is overcoming the stigma that machine-made equals cheap, low-quality cigars.

“Truth be told, the majority of machine-made cigars out there today in the U.S. are not being produced with premium tobaccos since, by design, they were developed to provide consumers with low-priced options, which is not the case for Royal Agio Cigars and some other premium tobacco manufacturers making small-format premium cigars,” explains Florez-Estrada. “We have to take the time, similar to premium handmade cigars, to walk them through our blends and the various premium cigar tobaccos sourced from around the world that come together to create a truly premium cigar experience in a more convenient, smaller, everyday format. We are proud to have the opportunity to present our high-quality premium cigarillo brands, like Panter, Mehari’s and Panther, to retailers looking for premium small cigars to offer their customers.”

“Truth be told, the majority of machine-made cigars out there today in the U.S. are not being produced with premium tobaccos since, by design, they were developed to provide consumers with low-priced options, which is not the case for Royal Agio Cigars and some other premium tobacco manufacturers making small-format premium cigars,” explains Florez-Estrada. “We have to take the time, similar to premium handmade cigars, to walk them through our blends and the various premium cigar tobaccos sourced from around the world that come together to create a truly premium cigar experience in a more convenient, smaller, everyday format. We are proud to have the opportunity to present our high-quality premium cigarillo brands, like Panter, Mehari’s and Panther, to retailers looking for premium small cigars to offer their customers.”