As tobacco use in the U.S. continues to decline, USTC is adapting to the changing market by expanding its customer base of both leaf export and consumer products. It has begun marketing its cut rag, strips and stems to more international customers and has also started strengthening its relationship with high-profile retailers and distributors throughout the U.S.

Value-Priced Quality

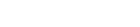

USTC also participates in the tobacco industry by making and distributing its own brands. Through its subsidiary, Premier Manufacturing, USTC has several national brands currently on the market including Wildhorse, 1839, Shield, 1st Class, Ultra Buy and Traffic. All of Premier’s brands are processed, blended and packaged in a cooperative-owned facility located in Timberlake, North Carolina. As with other parts of the business, the flue-cured tobacco used in these brands are all sourced from USTC’s member growers, which means they are a product of U.S. farmers and also come with a 100 percent satisfaction guarantee.

“All brands are American-owned, American-grown and American-manufactured,” says Schueller. “We proudly state, ‘A Product of U.S. Farmers,’ and this registered trademark truly resonates with our customer base, and we have seen sales increase since its inclusion.”

Price point and Premier’s commitment to being customer-focused has led to its success in the competitive cigarette category. Premier’s sales staff work with key retail and distributor customers to ensure they not only have premium tobacco products in stock but that they also have the promotional support needed to make a profit from them. Over the past few years, a significant investment has been made in Premier’s process. The company has upgraded its cigarette making and packing lines, and it has improved its filter making process. In an effort to improve product quality, the company has also added quality testing stations in its facilities to carry out real-time monitoring of its manufacturing process, which helps ensure the final product consistently meets specifications.

Investing in People

Investing in People

USTC’s concern for people extends to their leaf supplier and manufacturing partners by removing the burden of financing or accruing bad debt from the company’s crops. With USTC taking care of its U.S. growers, manufacturers and leaf suppliers do not have to pay the overhead for the teams of agronomists and field technicians that they normally would if they were growing crops in other countries. Also, because of the strict standards established by GAP Connections, child labor on USTC’s farms is virtually nonexistent according to independent audit results. USTC’s commitment to excellence has helped to set it up for success in the future, even with the increasing regulations and legislative obstacles the industry continues to face.

This story first appeared in the May/June 2019 issue of Tobacco Business magazine. Members of the tobacco industry are eligible for a complimentary subscription to our magazine. Click here for details.

– Story by Antoine Reid, an editor and digital content director for Tobacco Business Magazine. You can follow him on Instagram @editor.reid.